The substrate temperature in the PE-ALD process was varied from 200 ☌ downwards to room temperature (rt). In this paper we show a comparison of Al 2O 3 samples prepared by T-ALD and PE-ALD respectively based on ellipsometry and on X-ray photoelectron spectroscopy measurements (XPS). Furthermore to our knowledge there seems to be a lack in reports about dielectric parameters in dependence of the substrate temperature for PE-ALD as mostly comparisons are given at fixed temperatures or only for T-ALD samples. However characterizations based X-ray photoelectron spectroscopy (XPS) in dependence of the substrate temperature are not shown in that reviews.

The influence of the substrate temperature onto these parameters was discussed, also when a commercial 200 mm ALD reactor was used. Herein the typical parameters like growth rate per cycle (GPC), density and refractive index were determined by ellipsometry whereas the elemental composition was mostly deduced from Rutherford Backscattering Spectrometry (RBS). This group has reported also on the modeling of reaction regimes influencing the conformality of the PE-ALD process. Recently the Kessels group has reviewed the state of the art of plasma-assisted ALD and surface passivation schemes of Al 2O 3 prepared by ALD. The latter allows further the ALD use in organic and in particular flexible electronic applications or on thermally fragile substrates. Caused by the higher reactivity of the plasma generated oxygen radicals the PE-ALD extends the capabilities of ALD such as improved film quality, increased flexibility in process conditions, and is in particular preferred over thermal ALD for lower substrate temperatures due to lower impurity levels. Within the last decade the research have been extended to plasma enhanced ALD (PE-ALD) in which the H 2O as oxygen source is replaced by a plasma exposure (O 2, O 3).

The most commonly used ALD sequence for thermal ALD (T-ALD) is the pulsed alternation of trimethyl-aluminum (TMA) as metal source and water as oxygen source, respectively. Furthermore, Al 2O 3 ALD layers have shown their ability as gate dielectrics for future graphene based electronics. Here, in particular the excellent conformability of ALD growth over high surface area materials and its uniformity and self-termination were beneficially applied. This includes for example solar energy conversion systems like dye sensitized solar cells and water splitting devices or lithium ion batteries. Recently, there is a growing activity in covering photo-electrodes or electrodes by ultra-thin Al 2O 3 ALD layers for electrochemical energy generation and storage systems in order to enhance the efficiency and durability of such devices. Thin aluminum oxide (Al 2O 3) layers deposited by atomic layer deposition (ALD) have been investigated for several applications like surface passivation or encapsulation in organic and inorganic photovoltaic devices, interfacial buffering for high-k dielectrics, organic memories, and nano-laminates as well as work function modification, gas diffusion barrier or corrosion protection. Initial state energy shifts in all PE-ALD samples are observed which we attribute to a net negative charge within the films.

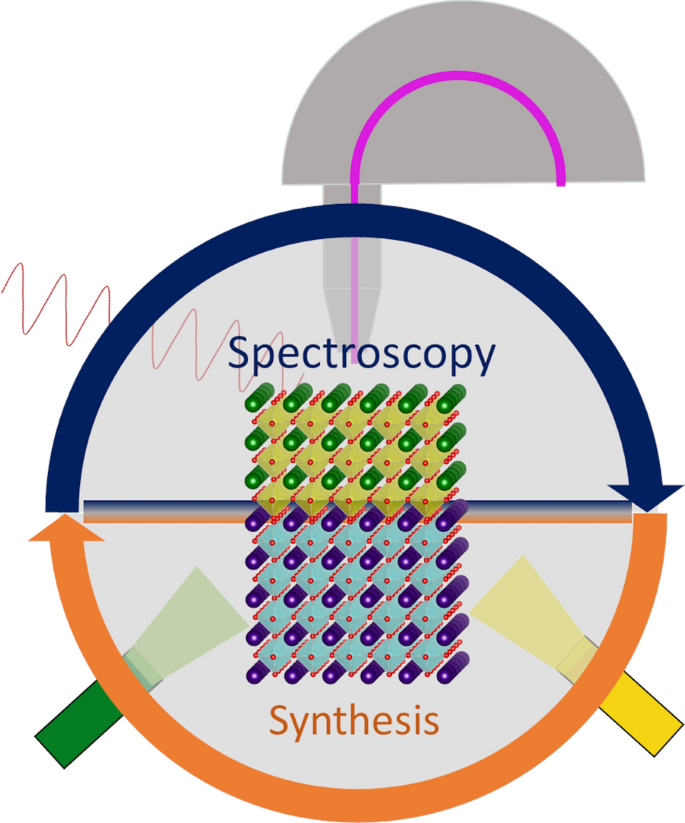

We also find a decrease of the refractive index and of the oxygen to aluminum elemental ratio as well as an increase of the growth rate whereas the homogeneity of the film growth is not influenced significantly. Reducing the deposition temperature down to rt leads to a higher content of carbon and CH-species. The PE-ALD films show an increased growth rate and lower carbon contaminations. However, in both also fragments of the precursor are integrated into the film. The 200 ☌ T-ALD and PE-ALD processes yield films with similar refractive indices and with oxygen to aluminum elemental ratios very close to the stoichiometric value of 1.5. We show data from spectroscopic ellipsometry (thickness, refractive index, growth rate) over 4” wafers and correlate them to X-ray photoelectron spectroscopy (XPS) results. The T-ALD Al 2O 3 layers were deposited at 200 ☌, for the PE-ALD films we varied the substrate temperature range between room temperature (rt) and 200 ☌. We report on results on the preparation of thin (<100 nm) aluminum oxide (Al 2O 3) films on silicon substrates using thermal atomic layer deposition (T-ALD) and plasma enhanced atomic layer deposition (PE-ALD) in the SENTECH SI ALD LL system.

0 kommentar(er)

0 kommentar(er)